A Microfluidics Breakthrough in Chip Cooling

Microsoft’s latest breakthrough in data center cooling leverages in-chip microfluidics to address one of the most critical challenges for next-generation AI chips: escalating heat generation. This technology presents a substantial improvement over traditional cold plate cooling, laying the foundation for more efficient, reliable, and sustainable AI infrastructure.

Why Data Center Cooling Needs a Revolution

Traditional cooling methods, such as air and cold plates, have reached their limits as AI chips grow more powerful and energy-dense. Cold plates, while effective, are separated from chip hotspots by multiple insulating layers, restricting their ability to dissipate heat. As workloads become spikier and chips are pushed closer to their thermal thresholds, this legacy technology will increasingly bottleneck progress and efficiency.

Microfluidics: Cooling at the Source

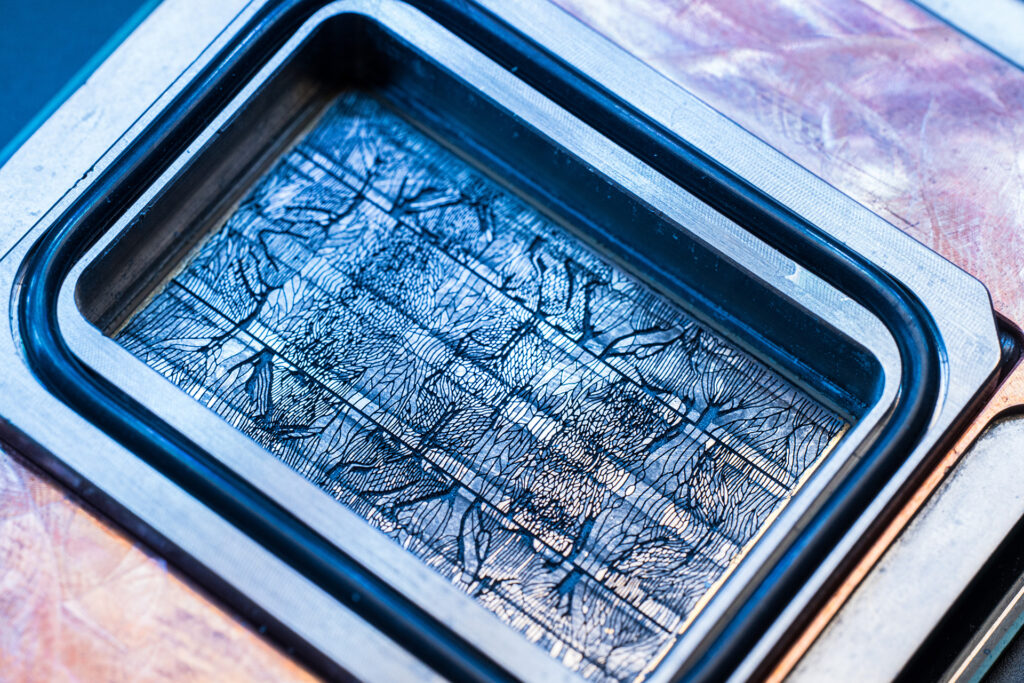

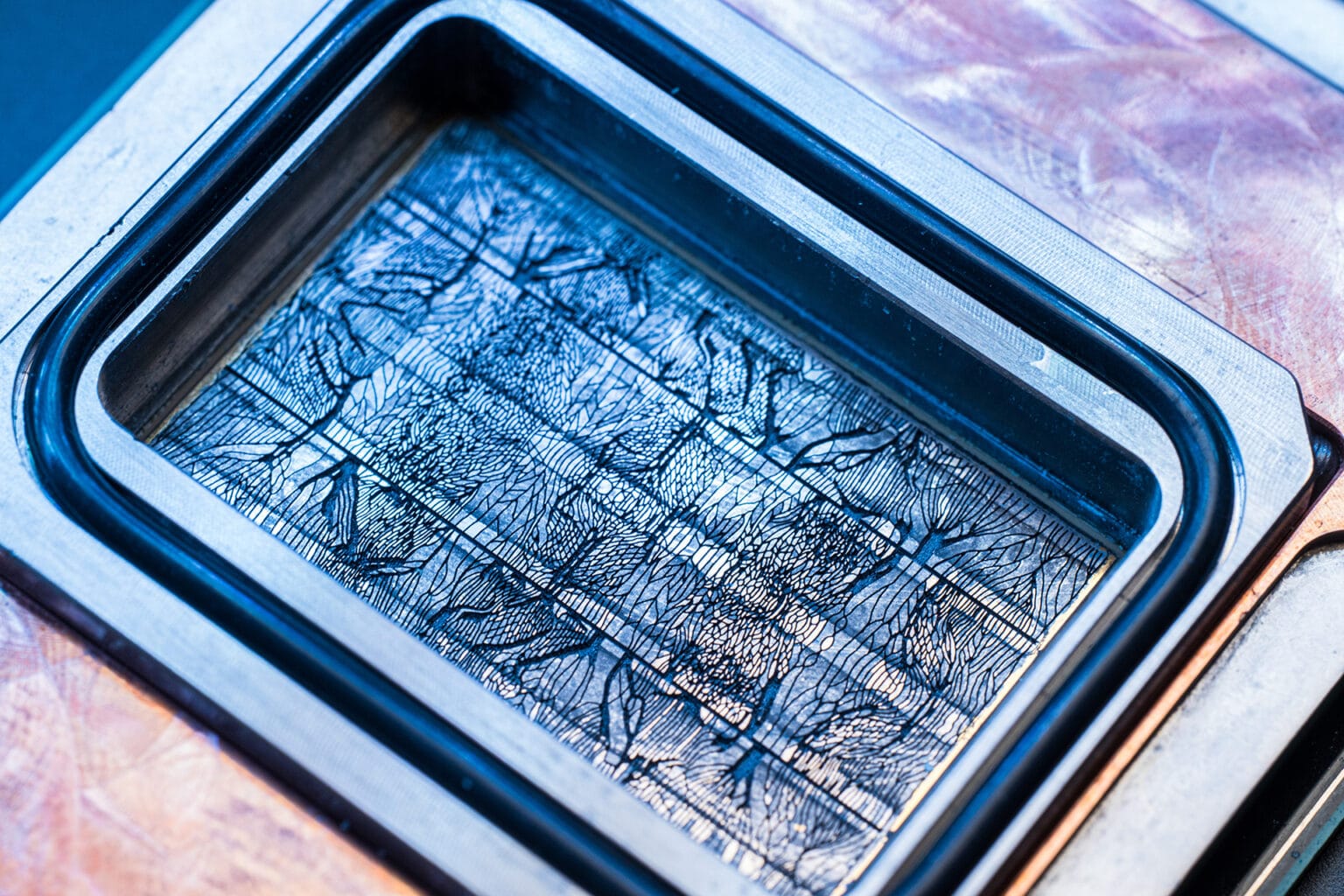

Microfluidics introduces a paradigm shift by etching microscopic channels directly onto the silicon surface. These channels, with dimensions comparable to human hair, allow coolant to flow precisely over the hottest parts of the chip. Bio-inspired designs, like those mimicking leaf veins, maximize efficiency by distributing coolant where it’s needed most. Microsoft’s collaboration with Swiss startup Corintis and the application of AI algorithms in channel optimization exemplify the multidisciplinary effort required to perfect this approach.

Performance, Reliability, and Sustainability

Lab tests show microfluidic cooling can remove heat up to three times more efficiently than cold plates and reduce maximum internal chip temperature by 65 percent, depending on the workload. This not only extends the reliability and lifespan of hardware but enables higher power density and overclocking—crucial for handling fluctuating AI workloads like Microsoft Teams calls. The result is a data center that can pack servers closer together without overheating, driving down latency and operational costs while also improving power usage effectiveness.

Enabling Next-Gen Chip Architectures

Microfluidic cooling may be the key that unlocks innovative chip structures, including 3D-stacked chips, which offer even greater computational performance by physically stacking silicon layers. In such designs, coolant could be routed through vertical structures similar to architectural pillars, making high-density and high-speed computing architectures viable at scale.

Moving From Prototype to Industry Standard

While Microsoft’s tests validated the concept and reliability of microfluidics, commercial deployment requires solving challenges like leak-proof packaging, optimized coolant formulas, and manufacturing integration. Microsoft’s systems-focused approach is already shaping the company’s custom Cobalt and Maia chips, built for energy efficiency and performance—further demonstrating commitment to innovation at every layer of cloud infrastructure.

Broader Impacts and Future Outlook

By adopting microfluidics, data centers not only reduce energy demands and operational stress on local grids, but also pave the way for more sustainable, compact, and scalable infrastructure. Microsoft aims to bring these advancements to its own first-party chips and, eventually, to the wider ecosystem, accelerating industry-wide innovation.

Microfluidic cooling represents a critical leap forward for AI at scale, promising tangible benefits for cost, reliability, speed, and sustainability. As hardware innovations remove bottlenecks from thermal design, software and AI capabilities can flourish, driving progress in cloud computing and beyond

Sources